Surface Numbering

The numbering of glass surfaces starts on the exterior and moves inward. LowE coatings are most commonly applied to surface 2, but are sometimes applied to other surfaces depending on the configuration.

We use some of the largest sealed units available, and thanks to our exceptional glazing specifications they also lead the industry in performance. Our glass can be tailored to control thermal transference, solar-energy transference, light transmittance, and more.

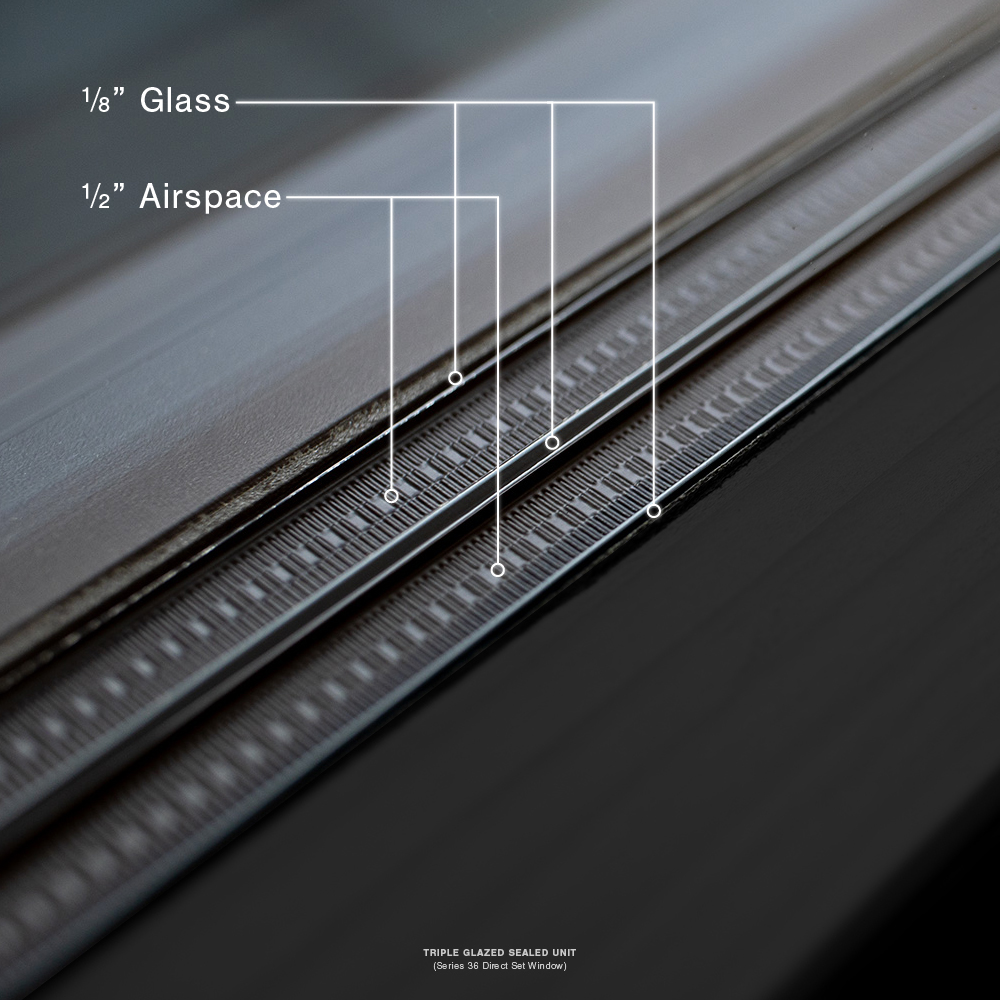

Loewen sealed units are built with minimum 1/8″ thick glass, though we often go much thicker. This offers greater strength and clarity over thinner glass, making our products more insulative, more soundproof, more resistant to impact, and considerably more resistant to stresses caused by fluctuations in temperature.

We also use 1/2″ airspaces filled with Argon gas. Argon is a non-toxic, colorless, and odorless gas that occurs naturally, it slows the transfer of heat through the sealed unit and, very importantly, stays perfectly clear.

A venting channel built into the sash helps dissipate any condensation or moisture should it occur. Our stainless steel spacer bars are less conductive than aluminum and structurally superior to silicone foam spacers, and our sash cladding does not touch the glass which reduces the opportunity for thermal conduction.

*This image shows our True Triple Glazing in our Picture/Direct Set window.

Incredibly thin layers of silver are added to one or more glass surfaces (most commonly surface 2) of our sealed units to reduce the amount of light transmissivity. This high-performance glazing system offers great thermal value in a variety of climate zones, and also protects furnishings by limiting much of the damaging ultraviolet radiation that causes fading and related damage.

Glass performance can be a complicated topic, the most important takeaway is this: you have options. We use the following terms to help communicate the many aspects of glass performance:

U-Value

How well a window keeps heat inside. The lower the number, the better the performance. Glass with a low U-Value is often used in colder climates to keep precious warmth inside the home.

Solar-Heat Gain

How well a window keeps Solar-Heat outside. The lower the number, the better the performance. It’s important to consider solar-heat gain in hot, sunny climates as you’ll probably want to keep that solar heat out. However, in the same hot and sunny climate, you may not be so worried about solar-heat gain for an elevation of your house that’s always in shade. Furthermore, houses in cold climates don’t mind a little solar-heat gain, anything to help keep the cold temperatures at bay.

Light Transmittance

How clear the glass is. The higher the number the clearer the glass. LowE window systems will ultimately reduce how much light is transmitted through a window, especially when your adding several layers of silver. You’ll also see light transmittance change when you move from a dual glazed sealed unit to a triple glazed sealed unit.

The last two digits of the LowE number represents the percentage of light transmittance. As the LowE configuration gets more aggressive, the number decreases, meaning less light is getting through.

We pioneered True Triple Glazing in the 1970’s, which is a testament to our approach on innovation. For premium energy performance, we’ve made triple glazing available across our entire product line.

Unlike triple glazing from other companies, we don’t reduce airspace thickness in our True Triple Glazing, which means you get three thick panes of glass, two 1/2″ airspaces filled with Argon gas, and multiple layers of LowE coatings. We pioneered our True Triple Glazing in the 70’s, a testament to how important this level of performance is to us. That’s also why we’ve made True Triple Glazing available across our entire product line.

Nick Wall celebrates 50 years of True Triple Glazing; and also dives into the world of high performance glazing in general.

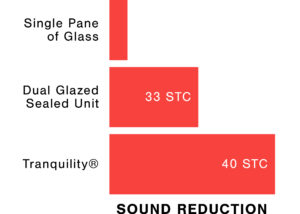

Loewen’s heavy frames, thick glass, and superior fit and finish already result in above-average sound attenuation, but we reduce sound transmission even further by implementing Tranquility® Glazing Systems. Tranquility® Glazing Systems consist of a 1/4” (6 mm) glass on the exterior, a 13/16” (21 mm) Argon filled space, and a 9/32” (7 mm) laminate pane of glass on the interior. Using a single number, the Tranquility® Sound Transmission Class (STC) rating identifies the sound transmission reduction of a glazing unit, operating casement units test out at STC40.

Neat+™ Glass is an ultra smooth surface made from silicon dioxide that harnesses UV rays to loosen dirt. Neat+™ Glass helps leave windows spotless with a quick rinse of water and preserves their cleanliness longer. Neat+™ Glass is offered with Preserve™ as standard to protect the Neat+™ surface.

Most Loewen sealed units are also equipped with Preserve™ protective film. This film layer is designed to protect sealed units during the construction phase, and is quickly and easily removed once your project is finished. Preserve™ is made from a low-density polyethylene and water-based adhesive, reducing masking and cleanup costs for painting and staining.

Additional options include a wide variety of novelty glass treatments. The examples below are just a small portion of the offerings that can be added to selected Loewen windows and doors. Please contact your local dealer for the full range of options and applications.

This door has been glazed with Narrow Reed glass. It creates the perfect kind of privacy, and plays with the light in a very striking way.

Windborne wreckage can impact homes during windstorms and hurricanes, with gusting, pervasive winds to follow. To protect the integrity and interior of homes, windows and doors must resist penetration and remain in place and intact. Impact designed laminated-glass windows and doors pass windborne debris impact tests, and even when broken, the glass fragments remain integral, adhering to the plastic interlayer, to preserve the building envelope. See our separate StormForce page for more information.